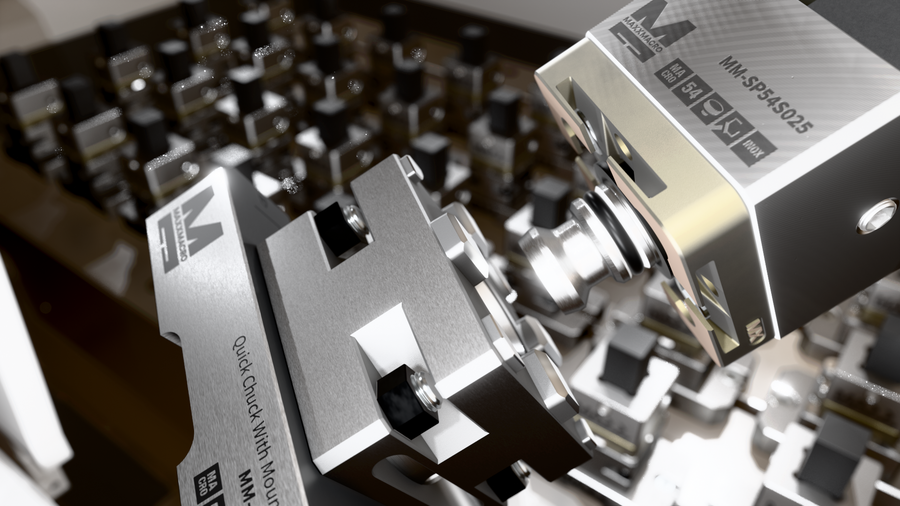

Are you new to workholding systems or looking to better understand how the MaxxMacro® system operates? In this video, we break down the core components—drawbar, pallet, and chuck—and explain how they work together to create an efficient, high-precision setup.

Why the MaxxMacro® System?

Reducing machine idle time is often more impactful than chasing faster machining speeds. The MaxxMacro® system is designed with this in mind: by enabling off-machine presetting and seamless inter-machine transfers, you can dramatically reduce internal setup time.

With a precise and consistent reference system, electrodes and workpieces can be moved between machines without realignment, helping you boost spindle utilization and overall productivity.

1. Drawbar

The drawbar is a key connector in the MaxxMacro® system. It locks into any MaxxMacro® pallet with a simple twist, enabling fast and secure clamping into a chuck.

✅ Universal compatibility: Every MaxxMacro® drawbar fits every MaxxMacro® pallet.

✅ Multiple models available: Choose the correct drawbar based on your chuck model.

📌 Tip: Always check the product description of your chuck to confirm which drawbar is required.

2. Pallet

MaxxMacro® pallets serve as the adaptable interface between your workpiece or fixture and the chuck.

They come in two main types:

-

Standard: Stainless cast versions for everyday applications.

-

MaxxPerformance: Precision-machined from solid 440C stainless steel for enhanced strength and durability.

📏 Available sizes: 54mm, 70mm, and MaxxMagnum—suitable for a wide range of workholding setups.

🛠️ You can mount workpieces or custom fixtures directly onto MaxxMacro® pallets.

✅ All MaxxMacro® fixtures come pre-installed with pallets, so you’re ready to go out of the box.

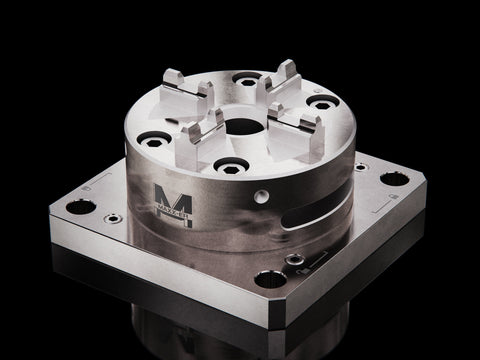

3. Chuck

The chuck is the heart of your MaxxMacro® setup — providing a stable, ultra-precise base for mounting any MaxxMacro® component. With repeatability of 0.002mm, it ensures consistent accuracy across setups and machines.

🧲 Clamping options:

-

Manual with quick bar

-

Manual with Allen key

-

Pneumatic models

🌊 Some chucks are designed for submerged operation, and a wide range of mounting plates are available to suit different machines and setups.

✨ Need something specific? Custom mounting plates can be made to order!

💡 Reminder: Your machine only makes money when the spindle is turning. MaxxMacro® helps you work smarter, not harder.