Categories

MaxxMacro 70 Self Centering MaxxVise 2.75" with Performance Pallet

€871,95

Regular price

€871,95 EUR

Sale

- Product Details

- Shipping & Returns

- Related News

- Dovetail Preparation with MaxxMacro Workholding Solutions

- MaxxMacro MaxxVise Self Centering Vise 2.75 & 4.725 Inch

- New Custom Lang Compatible Vice 4.725 Inch Capacity

- Well done Maxx Tooling - Self Centering Vise Nicholas Hacko Watch Maker in Australia

- The 2024 SKU Update for Enhanced Clarity and Compatibility

-

MAXX-FEATURES

MaxxMACROMaxxMacro 70Corrosion Resistant

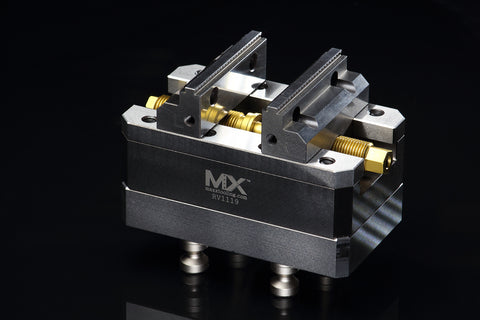

MaxxMacro 70 Self Centering MaxxVise 2.75" comes fully assembled and ready to use. This product is 100% cross-compatible with the System 3R Macro OEM system.

MaxxDesign Exclusive Features:

- High quality materials.

- 100% cross-compatible with OEM system

Product Information:

MaxxVise Self Centering Vise 2.75 Inch . MaxxMacro 70 is designed for high accuracy precision CNC equipment horizontal and vertical.

- Stainless Steel Construction 2.75" Maximum work piece

- Reversable jaws

- Bidirectional self centering repeatability .005MM

- Mounted and Centered on MaxxMacro 70 High Performance Premium Pallet

- The center of jaws are aligned and centered to the MaxxMacro pallet when the vise is closed.

- 100% cross compatible with System 3r Macro Systems.

- Max torque: 8Nm

If you are robotically loading we can adapt this vise to various grippers, stop buttons etc.

Product Details:

| Product Name | MaxxMacro 70 Self Centering MaxxVise 2.75" |

| SKU | MM-VISCS002 (MX-V70SMM) |

| Pallet Included | See print |

| System | MaxxMacro (System 3R 100% Cross-Compatible) |

| Repeatability | 0.002mm |

| Material | See above |

| Cross-Compatible | - |

| Dimensions | - |

| Weight | - |

Returns Policy

You may return most new, unused items within 30 days of delivery for a refund. There is a 20% restock fee if the item is returned due to customer error. The customer is responsible for the return shipping costs if the return is a result of your error (Not if received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the 'Complete Orders' link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

Shipping

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

International shipments it is the customers responsibility to determine if there are any taxes or import duties payable and to make arrangements to clear and pay these fees if applicable.Dovetail Preparation with MaxxMacro Workholding Solutions

Published on: Nov 13, 2024

Mastering Dovetail Preparation with MaxxMacro Workholding Solutions

In the world of precision machining, efficient and secure workholding is critical. Today, we're excited to showcase how MaxxMacro’s workholding solutions streamline the dovetail preparation process. This blog post will walk you through a workshop filled with MaxxMacro tools, demonstrating how their advanced features make dovetail machining faster, easier, and more efficient, ensuring the highest level of performance in your operations.

Setting Up Your Workpiece

Dovetail preparation begins by securing your workpiece with the MaxxMacro 70 Self-Centering Vise. This vise is designed to provide precision alignment and solid stability, so your workpiece stays perfectly in place throughout the entire machining process. Its ability to adjust and center the workpiece makes it an ideal tool for reducing setup times and increasing machining accuracy. By ensuring your workpiece is securely fastened, the self-centering vise guarantees flawless machining from the start.

MaxxMacro Multi-Rail Chuck Setup

Once the workpiece is secured, the MaxxMacro 70 Pneumatic Multi-Rail Chuck comes into play, providing powerful and adaptable clamping force. The chuck is versatile enough to accommodate various workpieces while ensuring that the clamping is secure and reliable. Whether you’re working on simple or complex jobs, the pneumatic multi-rail chuck offers flexibility and strength. This not only enhances machining efficiency but also reduces the risk of workpiece movement during machining, which can lead to precision errors.

Quick and Simple Dovetail Machining

The dovetail machining process with MaxxMacro is remarkably straightforward, consisting of a few efficient steps. With MaxxMacro’s well-engineered workholding solutions, the complexity of dovetail preparation is reduced to a simple, repeatable procedure. This ease of use means you can move quickly from setup to production, saving valuable time and minimizing the potential for errors. MaxxMacro's tools are designed with simplicity in mind, ensuring that even those new to dovetailing can achieve professional results.

Precision with the Optional Dowel Slot

MaxxMacro dovetail holders come equipped with an optional dowel slot, providing an added layer of precision for your machining operations. This feature allows for more accurate alignment and greater control during the machining process, ensuring your workpiece remains perfectly positioned. The dowel slot is especially useful in applications where even the smallest error can result in costly reworks. By integrating this feature into their dovetail holders, MaxxMacro ensures that your machining setup is as precise as possible, every time.

Superior Clamping Force and Stability

One of the standout features of the MaxxMacro dovetail design is its superior clamping force. The dovetail angle applies inward and downward force on the workpiece, ensuring stability even during heavy-duty machining operations. This design not only prevents the workpiece from shifting but also allows for greater machining precision, even under high-speed or high-pressure conditions. The result is smoother, more accurate cuts with minimal vibration or movement. This added stability is a game-changer, especially for complex or high-precision machining tasks.

Minimizing Material Waste

MaxxMacro's dovetail holders are engineered to use materials efficiently, minimizing waste and maximizing the value of your stock. Traditional clamping methods often result in unnecessary material loss, but with dovetail workholding, this waste is significantly reduced. The dovetail system distributes clamping force evenly, reducing stock consumption and part deformation. This not only lowers material costs but also ensures that each workpiece retains its integrity, leading to higher-quality finished products.

Versatility with MaxxMacro Dovetail Holders

MaxxMacro offers dovetail holders in four different sizes to suit various applications and workpiece dimensions. Whether you're working with small, intricate parts or large, bulky materials, MaxxMacro has the right dovetail holder for the job. This versatility ensures that you can handle a wide range of machining projects with ease. No matter the complexity or size of your workpiece, MaxxMacro’s dovetail holders provide the stability and precision you need for a successful outcome.

5-Axis Machining Made Easy

For those utilizing 5-axis machines, MaxxMacro's MaxxMagnum Manual Chuck Low Profile setup offers unparalleled access to your workpiece. The low-profile design ensures that your workpiece is easily accessible from multiple angles, allowing you to perform intricate machining tasks with ease. This setup is ideal for complex parts that require machining from various angles, enhancing both precision and efficiency. With MaxxMacro, 5-axis machining becomes more intuitive and manageable.

Handling a Wide Range of Materials

MaxxMacro dovetail holders are designed to accommodate a broad spectrum of materials, from delicate substances like graphite to ultra-tough, high-temperature alloys. This versatility means that no matter what material you're working with, MaxxMacro dovetail holders will provide the secure, stable workholding you need. Whether your project involves fragile materials that require a gentle touch or robust metals that need heavy-duty clamping, MaxxMacro’s solutions ensure optimal performance.

Seamless Workpiece Movement

One of the key advantages of the MaxxMacro system is its modularity, which allows for seamless movement of your workpiece between different setups and machines. This capability not only saves time but also maintains the precision and accuracy of your machining operations. Once your workpiece is mounted on a MaxxMacro holder, it can be easily transferred to other machines or setups without the need for realignment, keeping your workflow smooth and uninterrupted.

Rust-Proof Durability

MaxxMacro dovetail holders are crafted from 440C stainless steel, making them rust-proof, corrosion-resistant, and highly durable. This makes them ideal for use in harsh machining environments, including Wire EDM applications. The durable construction ensures that your MaxxMacro dovetail holders will withstand the test of time, providing reliable performance for years to come. By investing in these long-lasting, rust-proof solutions, you're safeguarding your machining operations against the wear and tear that can affect traditional workholding tools.

MaxxMacro MaxxVise Self Centering Vise 2.75 & 4.725 Inch

Published on: Jan 5, 2024

In the realm of CNC machining, where precision is paramount, MaxxTooling proudly presents the MaxxVise Self Centering Vise series. This innovative series, featuring the 2.75-inch and 4.725-inch MaxxMacro 70 models, is meticulously crafted to meet the exacting demands of high-precision CNC equipment in both horizontal and vertical setups.

Unleashing Precision for Smaller Workpieces

For tasks where precision is crucial, the Self Centering MaxxVise 2.75 Inch emerges as the ideal choice. With a torque of 20 Newton meters, this vise delivers exceptional accuracy for smaller workpieces, ensuring that every detail is meticulously crafted to perfection.

Key Features:

- Stainless Steel Construction

- 2.75" Maximum workpiece capacity

- Reversible jaws for versatile use

- 20nm Max Torque

- Bidirectional self-centering repeatability of .005MM

- Mounted and Centered on MaxxMacro 70 High-Performance Premium Pallet

Robust Force for Demanding Tasks

Stepping up to meet the most challenging tasks, the Self Centering MaxxVise 4.725 Inch takes CNC workholding to the next level. With a formidable torque of 70 Newton meters, this vise stands as a robust force, capable of handling workpieces with a diameter of up to 4.725 inches.

Key Features:

- Stainless Steel Construction

- 4.725" Maximum workpiece capacity

- Reversible jaws for versatile use

- 70nm Max Torque

- Bidirectional self-centering repeatability of .005MM

- 100% cross-compatible with System 3R Macro Systems

Precision Redefined with MaxxMacro 70

The MaxxMacro 70 design is optimized for high-accuracy precision in both horizontal and vertical CNC setups. Its features include reversible jaws, 20nm and 70nm max torque options, and bidirectional self-centering repeatability of .005MM. Moreover, it is 100% cross-compatible with System 3R Macro Systems, ensuring seamless integration into your existing CNC infrastructure.

Explore the MaxxVise Self Centering Vise Series on our page: MaxxTooling

In conclusion, the MaxxVise Self Centering Vise series redefines precision in CNC workholding. Whether you're working on intricate details or tackling demanding tasks, MaxxVise ensures that your workpieces are held securely and with utmost accuracy. Elevate your CNC machining experience – explore the possibilities with MaxxVise.

New Custom Lang Compatible Vice 4.725 Inch Capacity

Published on: Apr 20, 2020

One of Maxx Tooling's long time customers asked if we could configure our self centering vice to function in in current setup.

We produced our vice with stop button to function on customer Robodrill. Our vise was able to function in line with the customers current lang vises.

Maxx is able to customize virtually any of our vises to suit your specific needs and configurations.

Well done Maxx Tooling - Self Centering Vise Nicholas Hacko Watch Maker in Australia

Published on: Apr 21, 2018

We’re thrilled to share this glowing review from a master watchmaker in Australia who recently experienced the Maxx Tooling difference!

"Well done, Maxx Tooling! We’re impressed! On Friday, we placed an order for a pneumatic-held vise, and it arrived on Monday. That would be impressive even within Sydney metro—but this came all the way from Michigan, US! Maxx specializes in custom-engineered parts and tool holders. Their website may be low-key, but they’re laser-focused on quality and precision. The Maxx solution allows us to machine a part on our 5-axis Kern mill, then transfer it seamlessly to our Makino EDM, with zero loss in accuracy. One part, one holder, two machines, perfect precision. Good job apprentices!"

Thank you, Nick Hacko, for the kind words! We love seeing Maxx Tooling deliver game-changing precision and flexibility across industries.

Check out the full review here: http://nickhacko.blogspot.ca/2018/03/well-done-maxx-tooling.html

The 2024 SKU Update for Enhanced Clarity and Compatibility

Published on: Nov 8, 2024

At MaxxTooling, we're always looking for ways to improve your experience with our products and services. This year, we introduced a major update to our SKU system, designed to simplify product identification, improve inventory management, and enhance your overall experience. Here’s what this new system brings to the table—and how it benefits you.

What is a SKU? A SKU (Stock Keeping Unit) is a unique identifier used to track a product in inventory and make it easy to identify.

Why Did We Update the SKU System?

As our product family expands, we needed a improved SKU system that would deliver the following benefits:

- Consistency and Clarity: SKUs now follow a single, well-defined rule, making them easier to read and understand.

- Family and Product Matching: Each SKU reflects its product family, allowing you to identify compatible items more easily.

- Support for Future Growth: The new format makes it simple to accommodate new product introductions, family expansions, and variations.

- Integration with Adapter Plates and Custom Products: The revised structure also allows for easier integration of adapter plate codes, optional parts, and other customization options.

- Better ERP and Spreadsheet Integration: Standardized SKUs streamline data entry, making it easier to integrate with ERP systems, spreadsheets, and custom properties.

What Does the New SKU Format Look Like?

Our SKUs now follow a standardized, informative structure:

MX-XXXXMSSS(-O-CODE)

Here’s what each section means:

- Prefix (MX/MM): Identifies MaxxTooling or MaxxMacro as the source, with additional prefixes planned for future products.

- Family Code (XXXX): A four-character code indicating the product family.

- Material Code (M): One character indicating the material.

- Size Code (SSS): Three digits denoting the product’s size or model.

- Optional Code (O): A single character used for optional features, such as performance enhancements, index-disabled features, MXRefix systems, etc.

- Adaptation Code (-CODE): Optional codes for adapter plates, machine-specific modifications, or client custom modifications.

Revision Dates and Compatibility Page

The SKU update process has occurred gradually over the year, with different products receiving updates at different times. Each updated SKU has a specific Revision Date that you can check to ensure compatibility with your needs.

To make this transition easier, we’ve created a dedicated SKU Compatibility Page, where you can:

- Look up compatibility between old and new SKU formats

- Check revision dates for each product

- Access the latest product pages for detailed specifications

Visit the SKUs Compatibility Page

New Laser Markings for Improved Operator Experience

Along with our SKU system update, we’ve also made a significant improvement to the way we laser engrave our products. All of our items now feature new, detailed laser markings that provide essential product information directly on the part. This includes data such as ports, maximum torque values, and other key specifications. These updates make it easier for operators to quickly identify important features, improving workflow efficiency and reducing the chance of errors. The enhanced laser markings are part of our ongoing commitment to making your experience with our products as seamless and efficient as possible.

Our Commitment to Continual Improvement

Updating our SKU system is just the beginning. As we continue expanding and enhancing our product offerings, we’ll keep refining this system to support future growth and product variations. Our goal is to make it as easy as possible for you to select, track, and integrate our products into your workflows.

Thank you for choosing MaxxTooling as your workholding partner. Please explore our SKU Compatibility Page for more information, or feel free to reach out if you have any questions.

*This update was applied to the MaxxMacro® and MaxxMagnum® brands, but currently does not apply to Maxx-ER® or MaxxUPC®.